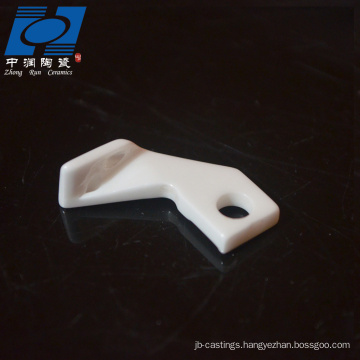

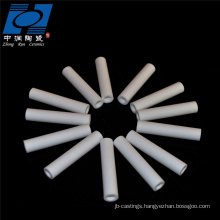

zirconia ceramic sealing part price

Product Description

| Zirconia Ceramic sealing part price | ||

|---|---|---|

• All items According to client's drawing

| Product Description |

| Product name | zirconia ceramic sealing part price |

| Place of Origin | Jiangsu, China(mainland) |

| Brand Name | Zhong Run |

| Type | Insulating Ceramic |

| Material | Zirconia |

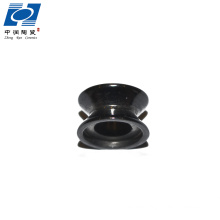

| Color | White, Black |

| Size | Customzied |

| Shape | Custom-shaped |

| Producing Method | Hot pressing/Dry pressing |

| Design | According to client's drawing or samples |

| Payment | T/T, Western Union |

| MOQ | 100pieces |

| Packing | Carton /Pallet/Wooden case (According to clients requirement) |

| Delivery time | Standard Product: Within 3 days |

| New developed items: 15days | |

| Application | Heating |

| Features | 1. Many kinds of insulated ceramics available |

| 2. It can satisfy constant's technical request | |

| 3. Good lead-heat capability | |

| 4. High resistance | |

| 5. High temperature and high voltage resistant |

machinable zirconia ceramic part selected raw materials

Heat insulating properties and oxygen-ion conductivity indicate zirconia has potential for use in a wide variety of applications - everything from telecommunications to the new energy of the future and environmentally beneficial products.

Zirconia offers chemical and corrosion resistance to temperatures well above the melting point of Alumina. In its pure form crystal structure changes limit mechanical applications, however stabilized Zirconias produced by addition of Calcium, Magnesium or Ytrium Oxides can produce very high strength, hardness and particularly toughness. In addition the material has low thermal conductivity and is an ionic conductor above 600°C. This has lead to applications in oxygen sensors and high temperature fuel cells.

| Zirconia Ceramic Technical Parameter |

| Ingredient | Wt% | ZrO2+Y2O3 |

| Density | g/cm3 | ≥6.0 |

Rigidity | Gpa | >11 |

Flexural strength | Mpa | 1150 |

| Toughness | Mpa.m0.5 | 9 |

Crystal grain size | μm | <0.5 |

Flexibility | Gpa | 200 |

Coefficient of heating conductivity | w/m.k | 3 |

Coefficient of heating expansion | X10-6/k | 10 |

Technical process for producing zirconia ceramic insert

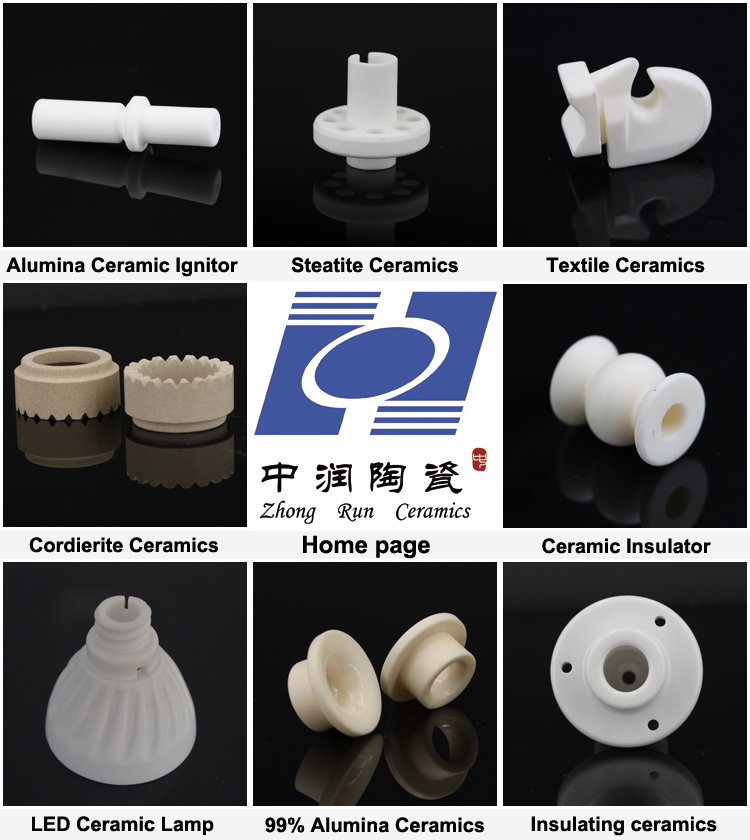

| Hot-selling Products |

| Main Raw Materials |

|---|

Alumina ceramics

Alumina Ceramic may be used in applications that require high elevated temperatures, High dielectric strength, wear or corrosion resistance, excellent electrical resistance, high temperature capability. High Electrical insulation.

Zirconia ceramics

Zirconia (ZrO2) is a unique advanced ceramic.

Products manufactured from zirconia powder exhibit superior mechanical properties such as high strength and flexibility.

Steatite ceramics

Steatite is used to support heating elements in electric heaters, toasters, and ovens.

Steatite is a good high voltage insulator.

It holds up under thousands of volts without breaking down.

Cordierite ceramics

The main chemical ingredient of Cordierite Ceramic is 2MgO·2Al2O3·5SiO2, main material is alumina, steatite, clay, feldspar, etc.

Manufactured by normal ceramic technic, can be used for loop frame work, insulators of arc-resistance, element of composite materials, burnable nozzle of electrical insulators, etc.

| Professional Industrial Ceramics Manufacturer

Nancy Yixing Zhong Run Ceramics Technology Co., Ltd

Add: Luojian Industrial .Dingshu.Yixing City ,Jiangsu Province .China Tel: +86-510-87490978 Fax: +86-510-87487578 Mobile: +86-13901533340 Web:

|

|---|

Yixing Zhong Run Ceramics Technology Co.,Ltd

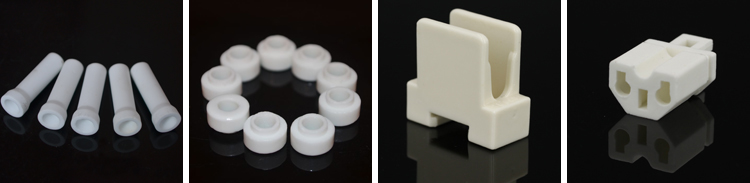

is a manufacturing company specialized in pressing Industrial Ceramics.

We make use of several forming and machining techniques to process components made from Alumina Ceramics, Steatite Ceramics, Zirconia Ceramics, Cordierite Ceramics, Mgo Ceramics, Corundum Ceramics etc. These materials may be used in applications that require wear or corrosion resistance, high temperature capability, abrasion resistant, electrical resistance. Our mainly materials are widely used in electrical appliance industry, Automotive industry, Mechanical Industry, Led lighting industry, Heating industry, Electrothermal Industry, Engineering Industry etc.

Zhong Run Ceramics believes in Manufacturing Quality products and delivers the products as per the customers drawing or samples.

We aim for excellence by setting Superior standards of performance and Commitments!

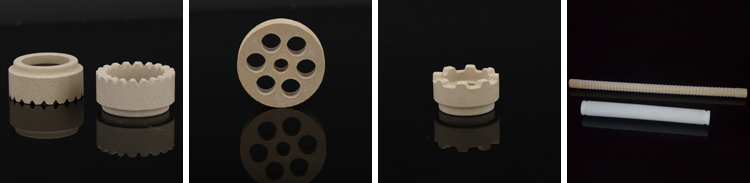

Moulding

The moulding methods are manual, automatic and dry pressing. machinable zirconia ceramic part are made by these three methods.

Sintering

Our company has two kilns, which have advantages in similar enterprises. We can burn more zirconia ceramic insert in a short time.

Packing

When the zirconia ceramic parts is finished, the person will be responsible for the packing.

Q1. Is it available to provide customize products?

A: We always support custom-made spark plug ceramic insulator as per clients' different raw material, specification and finish treatment.

Q2. How can you get quotation?

A: Please kindly send me your drawing with technic requirement and demand quantity.

If you don’t have the drawing,please kindly courier samples to us.

We will quote our best price in 24 hours

Q3. Are you a factory or trading company?

A: We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Contact us if you need more details on Machinable Zirconia Ceramic Part. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Zirconia Ceramic Insert、Zirconia Ceramic Parts. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Zirconia Ceramic

Premium Related Products