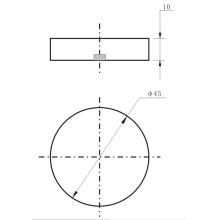

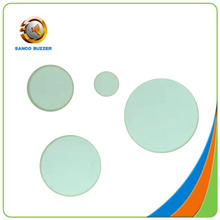

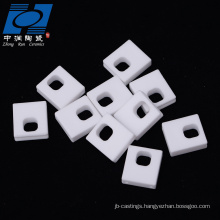

Dry Pressed Round 99.5% Alumina Ceramic Disc

| Payment Type: | T/T,Paypal,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 100 Piece/Pieces |

| Delivery Time: | 30 Days |

| Packaging: | Export carton |

|---|---|

| Productivity: | 100,000 sets/month |

| Brand: | Jinghui ceramics |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | China |

| Supply Ability: | 500,000 sets/month |

| Certificate: | RoHS |

| HS Code: | 8547100000 |

| Port: | Shenzhen,HongKong,Shanghai |

Basic Info

Model No.: JH.CS.006

Click on the follow link to find out more information: https://www.ceramictek.com/industrial-ceramic-plate/

Company Info

- Company Name: Jinghui Industry Ltd.

- Representative: Saiwu Tan

- Product/Service: Metallized ceramics , Precision ceramics , Pepper Grinder Mechanism , Ceramic Grinding Mechanism , Alumina Ceramic Plate , Ceramic Substrate

- Capital (Million US $): 5,000,000RMB

- Year Established: 2008

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 71% - 80%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 10

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: ZhongLian Village, LengShuiJiang City, Loudi, Huanan

- Contact Person: Mr. Andy Chen

- Tel: +86-755-26759158

Premium Related Products

Other Products

Hot Products

High Quality Custom Ceramic Burning Plate95% Alumina Ceramic For SensorGood Alumina Ceramic BeadsThermostat Ceramic(Steatite Ceramic)High Quality Ceramic Chip for MassageHigh Quality Resistance Alumina CeramicGreat Supplier Alumina Ceramic DiscBest-selling Ceramic Bushing InsulatorGood Sale Alumina Ceramic Substrates3mm ceramic pinHigh pressure car ceramic washerInsulating Alumina Ceramic Heating Element99% al2o3 alumina insulator ceramic tubeLED Lighting ceramic lamp holderCustom Made Glazed Alumina Ceramic IgnitorIndustrial Ceramic Plunger