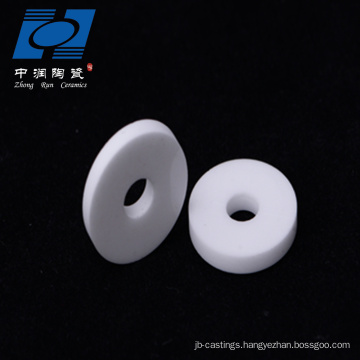

Ceramic disc faucet valve ceramic insulator

Product Description

Ceramic disc faucet valve ceramic insulator

We manufactures custom technical ceramics, covering a wide range of customer requirements .We make use of several forming and machining techniques to process components made from alumina Ceramics.

| Product Description |

| Product name | Ceramic disc faucet valve ceramic insulator |

| Place of Origin | Jiangsu, China(mainland) |

| Brand Name | Zhong Run |

| Type | Insulating ceramics |

| Material | Alumina |

| Color | White |

| Size | Customzied |

| Shape | Custom-shaped |

| Producing Method | Hot pressing/Dry pressing |

| Design | Custom |

| Payment | T/T, Western Union |

| MOQ | 1000pieces |

| Packing | Carton /Pallet/Wooden case (According to clients requirement) |

| Delivery time | Standard Product: Within 3 days |

| New developed items: 15days | |

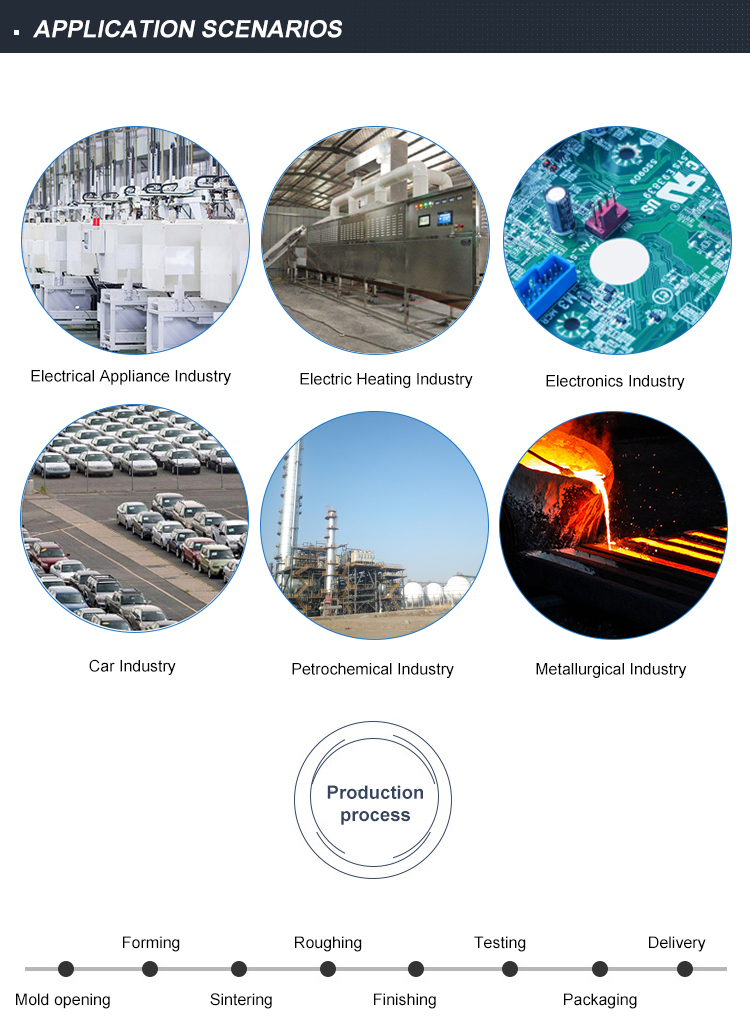

| Application | Heating |

| Features | 1. Many kinds of insulated ceramics available |

| 2. It can satisfy constant's technical request | |

| 3. Good lead-heat capability | |

| 4. High resistance | |

| 5. High temperature and high voltage resistant |

| Alumina Ceramics Technical Parameter |

| Alumina Content | 80-85% | 90-96% | > 99.5% | 99% |

| General Application | Lower Cost Electrical & Mechanical | High Strength, Wear Resistant, Electronic, Insulating, Mechanical, Structural & Metalizing | Extremely High Purity, Temperature & Strength; Excellent Corrosion & Wear Resistance | Porous, Easily Degassed & Machinable |

| Porosity (%) | 0-.05 | 0-.05 | 0-.05 | Variable |

| Density (gm/cm3) | 3.45-3.50 | 3.55-3.75 | 3.75-3.95 | 2.4 |

| Flexural Strength (kpsi) | 35.0-40.0 | 40.0-50.0 | 50.0-55.0 | - |

| Comprehensive Strength (kpsi) | 260.0 | > 300.0 | > 300.0 | - |

| Tensile Strength (kpsi) | 15.0-20.0 | 20.0-28.0 | 20.0-28.0 | - |

| Linear Coefficient of Thermal Expansion ((cm/cm/°C) 25-300°C 25-700°C) | 5.9X10-6 6.5X10-6 | 6.3X10-6 7.0X10-6 | 6.5X10-6 7.5X10-6 | 6.5X10-6 7.5X10-6 |

| Dielecctric Constant at 25°C (1 MH 10 MH) | 8.5-8.9 8.4-8.8 | 9.2-9.8 9.0-9.6 | 9.5-9.9 9.3-9.7 | - |

| Dielectric Strength (Volt/mil) | 200 | 225 | 225 | - |

| Te Value (°F °C) | 1472 800 | > 1832 > 1000 | > 1832 > 1000 | > 1832 > 1000 |

| Thermal Conductivity at 25°C (cal/sec/cm2/cm/°C) | .03-.04 | .04-.06 | .07-.08 | - |

| Thermal Shock | Good | Good | Good | Good |

| Safe Use Temperature (°F °C) | 2550 1400 | 3000-3100 1650-1700 | 3275 1800 | 3275 1800 |

Moulding

The moulding methods are manual, automatic and dry pressing. Ceramics are made by these three methods.

Sintering

Our company has two kilns, which have advantages in similar enterprises. We can burn more ceramic insulator bead in a short time.

Packing

When the ceramic insulator bead is finished, the person will be responsible for the packing.

Contact us if you need more details on Ceramic Disc Faucet Valve. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ceramic Disc Insulator、Ceramic Disc. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Hot Sale Ceramic > Alumina Ceramic Base

Premium Related Products