Hans Superabrasive Vitrified Internal Grinding Wheels confirm to the latest standards and world class technology to fulfill the requirements of Automobile ,Bearing And Engineering Industries.

Ceramic grain wheels are truly advancement in precision grinding. The ceramic grains used in these wheels have submicron crystal structure in each grain. The grain sharpens continually exposing fresh sharp cutting edges during grinding. It is a premium abrasive for hard to grind material in pressure, high productivity applications.

Suitable for surface grinding, external and internal cylindrical grinding, tool room grinding, gear and spring grinding and Bearing industries .

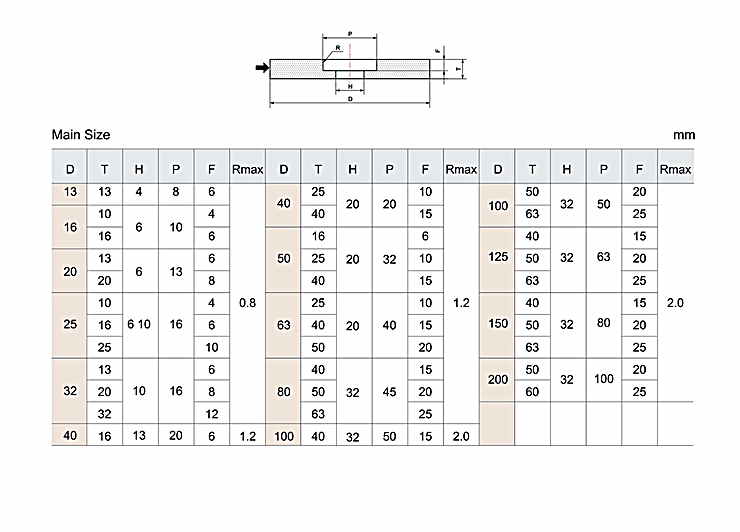

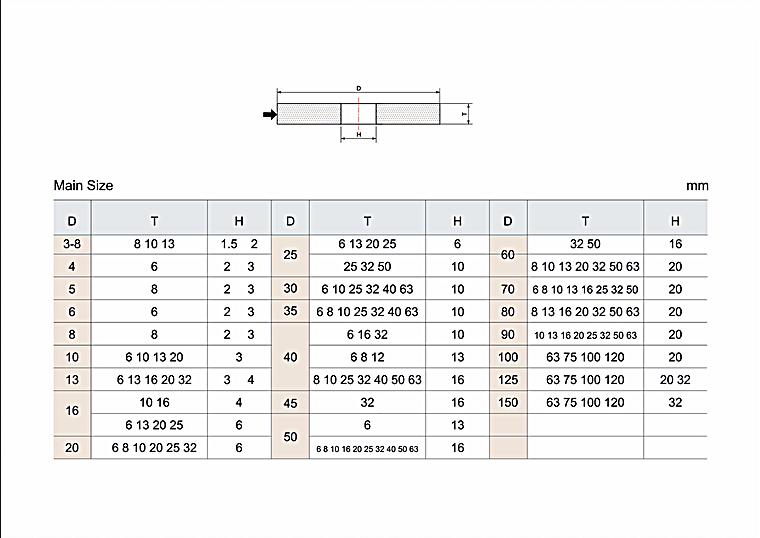

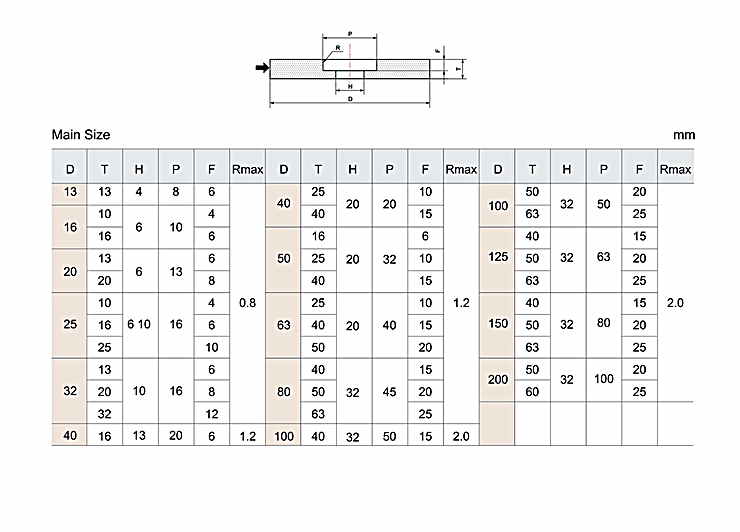

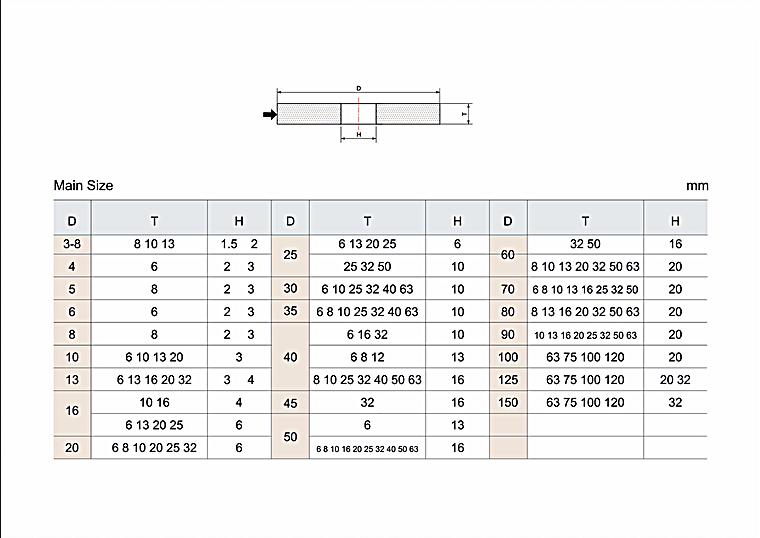

Internal Grinding Wheels can be designed and developed as per customer specifications to meet the specialized and specific requirements of growing clientele .

Benefits of Ceramic Grinding ( CG )

- Faster material removal.

- Reduction in cycle time.

- Improved form retention ability.

- Ideal for CNC Grinding Machine application.

- Less metallurgical damage due to cooler cutting action.

- Less dressing, efficient cutting.

- Better productivity.

Suitable for surface grinding, external and internal cylindrical grinding, tool room grinding, gear and spring grinding and bearing Industries.

Cylindrical grinding may include all outside diameter grinding, even though the finished workpiece is not a cylinder. The workpiece may be conical in shape or consist of a special form, ground with a wheel dressed into a specific shape. Wheels in this category are used for grinding works which are held between centres and chucks.Requirements in cylindrical grinding vary from fast stock removal, where rough finish is allowed, to ultra-smooth finishing, which is called mirror finish. Wheels with coarse grit and rough dressing are suitable for fast stock removal. In contrast, wheel with fine grit and smooth dressing result in smooth finish. Hard material requires softer wheels than soft material in the same wheel dimension. Workpieces with small diameters or sharp corners, finer grit is more important than harder grade. Workpieces with wide shoulders require softer and coarser wheels, particularly when the workpiece is hardened.

\

Contact us if you need more details on OD Internal Abrasive

Grinding Wheel. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cylindrical Abrasive Grinding Wheels、Centerless Cylindrical Abrasive Grinding Wheels. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Abrasive Precision Grinding Wheels